Precision in Test & Instrumentation

A Partner for ATE, Analytical Instruments, and RF Test

Measuring Up to the Task

The Test and Instrumentation (T&I) market is quickly growing, driven by ever-changing technologies that measure, analyze, display, test and record data. Advances in optical, RF, acoustic, and other sensors has enabled entirely new applications like IoT that have propelled the market forward. Increased demands for consumer products has led to high-volume production that now depends on automated test equipment to meet their throughput requirements.

Because many T&I products serve regulated markets including Defense, Space, Medical and Semiconductor, they find themselves beholden to their stringent requirements. These demands call for automated test equipment and functional testers to test new designs prior to volume production.

Measuring Up to the Task

The Test and Instrumentation (T&I) market is quickly growing, driven by ever-changing technologies that measure, analyze, display, test and record data. Advances in optical, RF, acoustic, and other sensors has enabled entirely new applications like IoT that have propelled the market forward. Increased demands for consumer products has led to high-volume production that now depends on automated test equipment to meet their throughput requirements.

Because many T&I products serve regulated markets including Defense, Space, Medical and Semiconductor, they find themselves beholden to their stringent requirements. These demands call for automated test equipment and functional testers to test new designs prior to volume production.

The Pursuit of Perfection

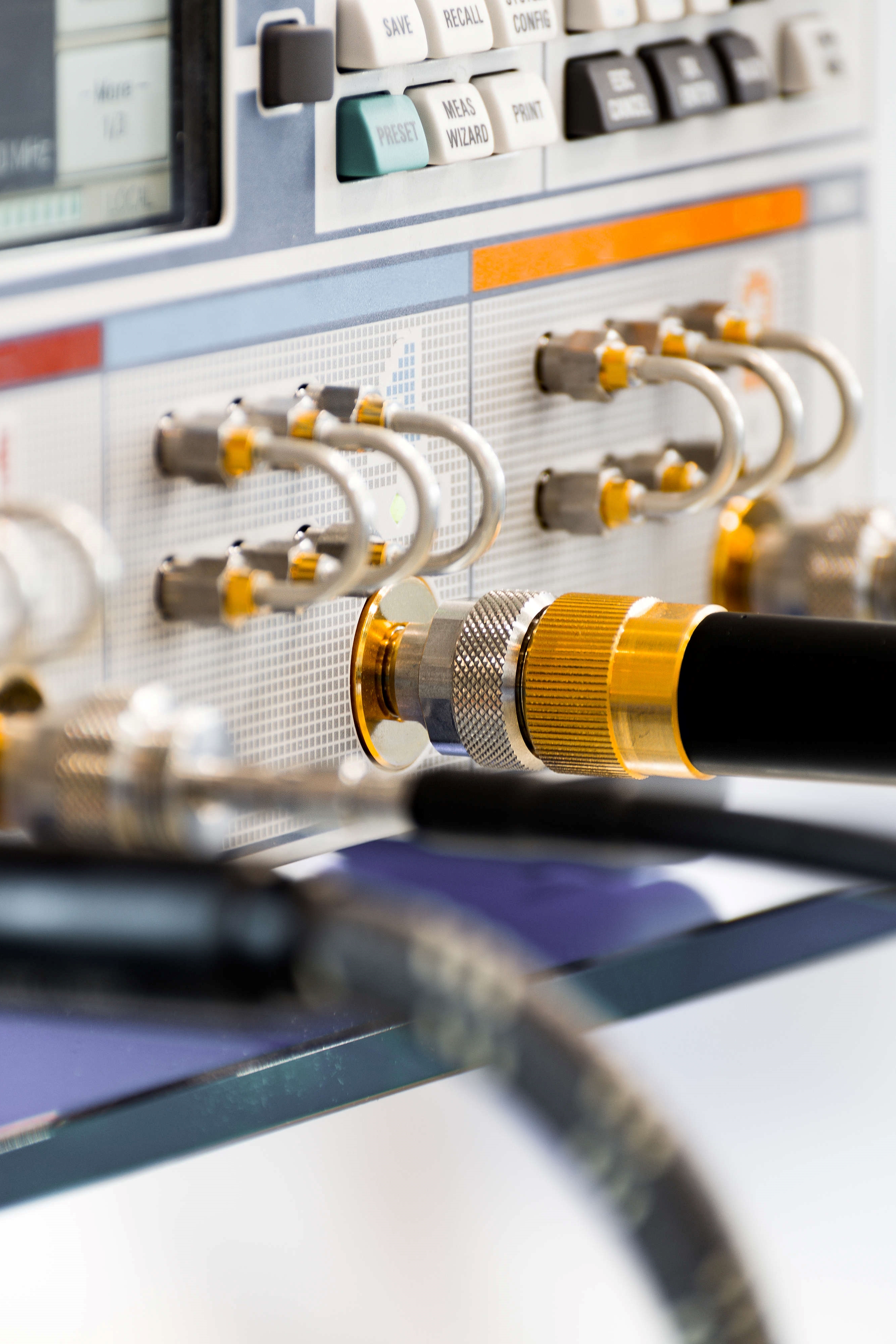

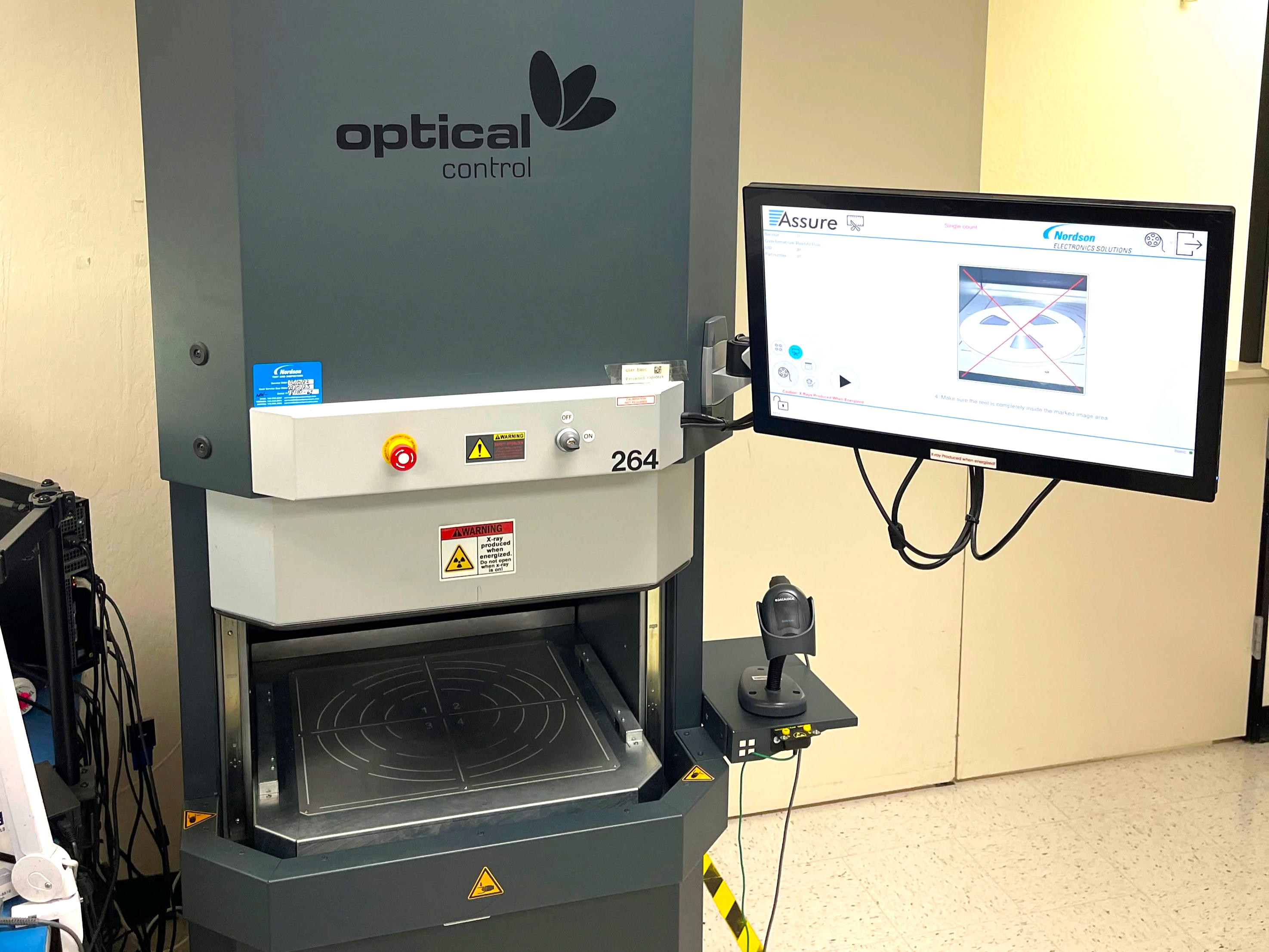

Naprotek manufactures technology in every part of the test and instrumentation ecosystem, building systems that deliver accurate results for new solid-state electronics, high-performance silicon processor load boards, and RF performance testing. We combine efforts from engineering, quality, test, and manufacturing know-how to deliver solutions to our customers in an accurate and cost-effective manner.

Our job is to provide continuing support to the advancement of technologies which influence our lives in areas including artificial intelligence, automation, microelectronics, RF design, sensors, silicon photonics and high-speed wireless. Our test and instrumentation customers deliver systems that perform automated and RF testing, various forms of inspection, performance, and reliability screening of components.

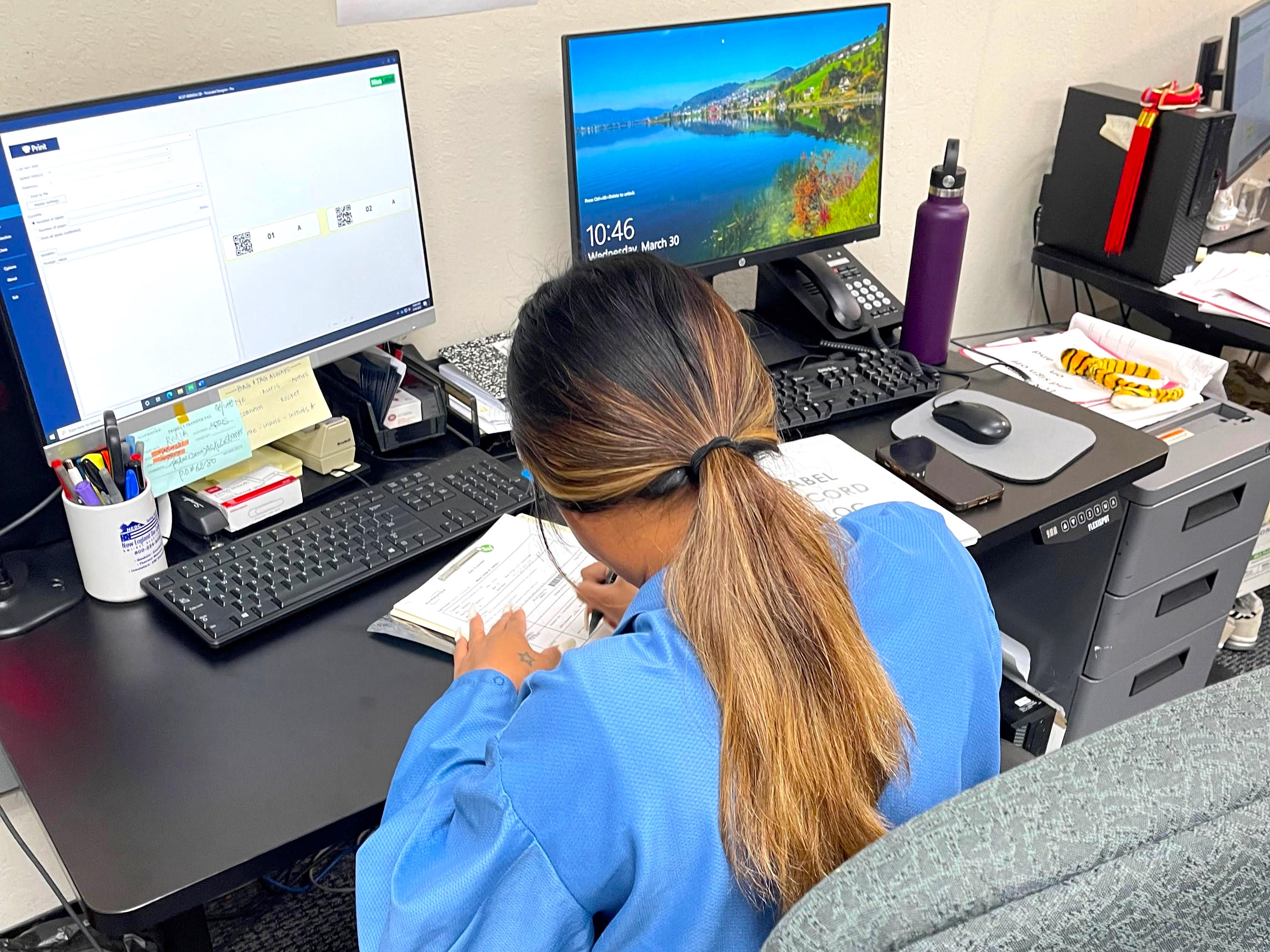

Program Management

Supply Chain Management

- Bill of Materials (BOM) scrub

- Build-To-Order, Configure-To-Order (BTO, CTO)

- Return Merchandise Authorization (RMA) Processing

- Counterfeit parts mitigation

Quoting

- Excellent with high mix SKUs

- Optimized for prototype, R&D builds

- Consigned, hybrid, turnkey

- Parts availability and substitutes

Ahead of the Curve

There will always be further advancements in technology and the burden of creating state-of-the-art test solutions to match. From 5G and 6G infrastructure deployments, sub-5 nanometer semiconductor wafer topologies, to millimeter-wave radios in communications, the T&I industry will be a fast follower to insure effective and reliable electronics.

Some devices Naprotek assembles today include:

- Automated Test Equipment (ATE)

- Inspection equipment

- Load boards

- Logic, protocol, and spectrum analyzers

- Probe cards

- RF generators & RF performance testing

- Scientific equipment

- Test & measurement equipment

Visit our Services page to learn more about our manufacturing capabilities.