Case Study: Opsis IQ

Improving Health Through Nutrition Insight

Addressing the Need

Opsis Health is a team of technology, nutrition, fitness, and business visionaries dedicated to revolutionizing the health of people and the planet through technology.

The company developed a consumer appliance, called the Opsis IQ, which works to train a cloud-based library and machine learning algorithm for nutrition tracking. The Opsis IQ is a mechatronic device that weighs a plated meal and, using a mobile phone, guides a three-dimensional visual scan in a consistent and repeatable way.

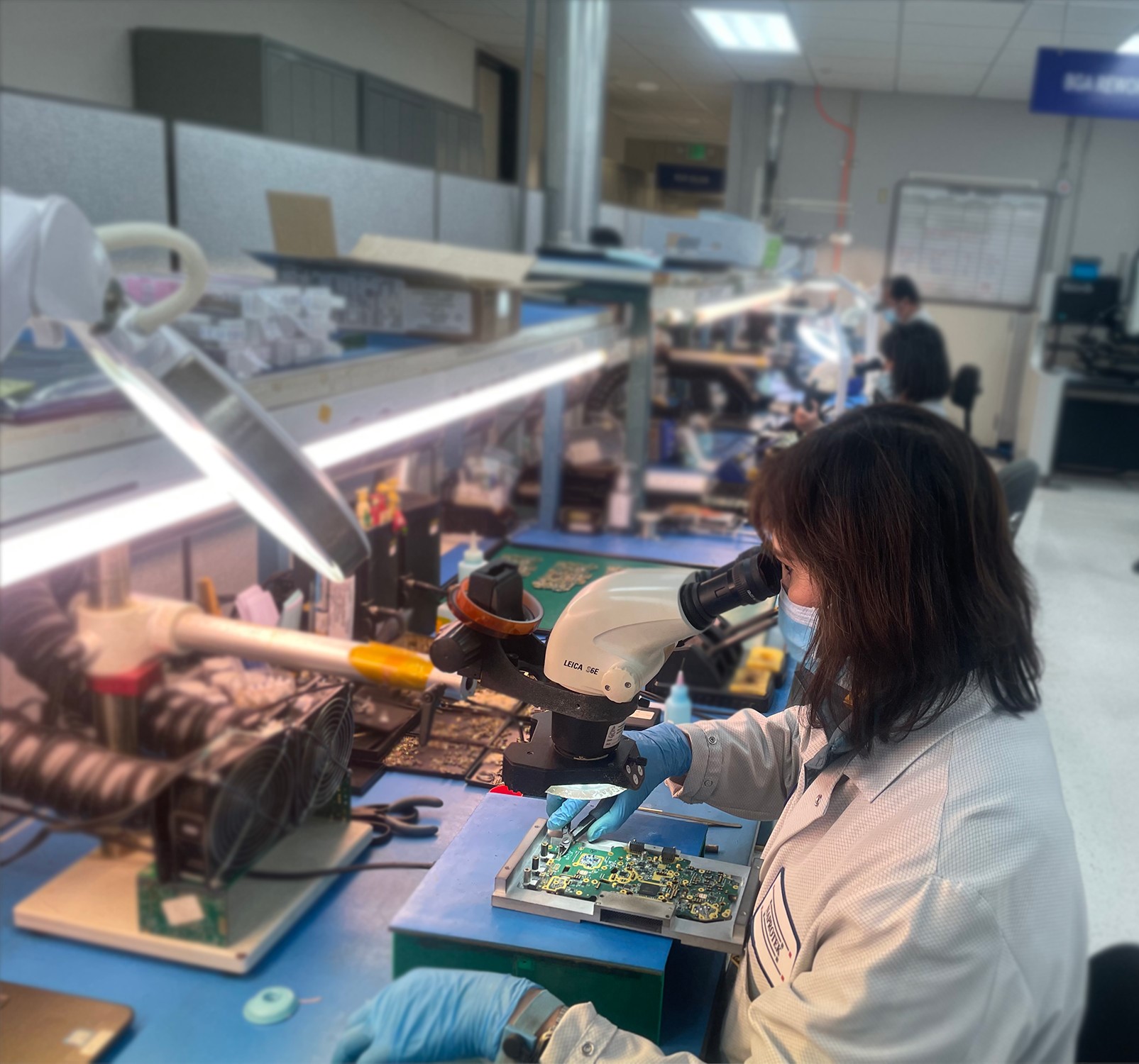

Opsis engaged Naprotek in the development of the IQ to perfect the design for production. Opsis needed a manufacturing partner for the IQ to establish manufacturing processes, refine the design, and to produce an initial batch of units for testing and evaluation by their industry partners.

Addressing the Need

Opsis Health is a team of technology, nutrition, fitness, and business visionaries dedicated to revolutionizing the health of people and the planet through technology.

The company developed a consumer appliance, called the Opsis IQ, which works to train a cloud-based library and machine learning algorithm for nutrition tracking. The Opsis IQ is a mechatronic device that weighs a plated meal and, using a mobile phone, guides a three-dimensional visual scan in a consistent and repeatable way.

Opsis engaged Naprotek in the development of the IQ to perfect the design for production. Opsis needed a manufacturing partner for the IQ to establish manufacturing processes, refine the design, and to produce an initial batch of units for testing and evaluation by their industry partners.

FOCUSED ON THE SOLUTION

Naprotek worked collaboratively with Opsis engineers to establish a manufacturing workflow, recommend design changes, component alternates, assembly process modifications, in-circuit and functional testing, and packaging. From hand assembly and manual processes around the printed circuit board assemblies (PCBA), to system assembly and testing, Naprotek’s goal was to stabilize the design of the Opsis IQ and to establish production processes in a scalable way.

Using Design for Manufacturability (DFM) principles, Naprotek identified key opportunities in the bill-of-materials (BOM) to document, formalize, and reconcile component selection and assembly instructions. Naprotek’s electronics manufacturing experts scrutinized every assembly step in the production of the Opsis IQ in order to identify areas where the electrical or mechanical integrity of the system could be compromised.

READ THE WHOLE STORY

Download The Case Study Now To Learn How Naprotek Prepared The Opsis IQ For Volume Production.

To Learn More About Opsis Health, Visit Their Website.

.png?width=1428&name=Opsis%20Carousel%20rendering%20(2).png)

“Thanks to Naprotek for building our Opsis IQs to such exacting standards! The pilot units have been outstanding. We know that your attention to detail and an inclination to go beyond the “good enough” has been instrumental in producing a great product.”

Kevin Grundy

Chief Executive Officer

Opsis Health